Flavor Training

We offer customized training programs on a variety of topics, such as flavor trends and flavor development. Topics can be customized based on your industry or interest.

Manufacturing Capabilities

Our manufacturing capabilities include, but are not limited to: dry flavor and color blending, spray drying and encapsulation, thermal processing, liquid flavor compounding, vitamin and nutraceutical blending, extraction, emulsions, distillation, oleoresins, portion packaging for retail, high-speed packaging, and canning. We also provide custom product solutions to meet the specific manufacturing needs of our customers. Our geographical locations provide continuity of processes and distribution expertise in servicing our customers.

Packaging Capabilities

We offer an assortment of liquid, powder, and paste portion packaging along with various sizes of private label retail packaging.

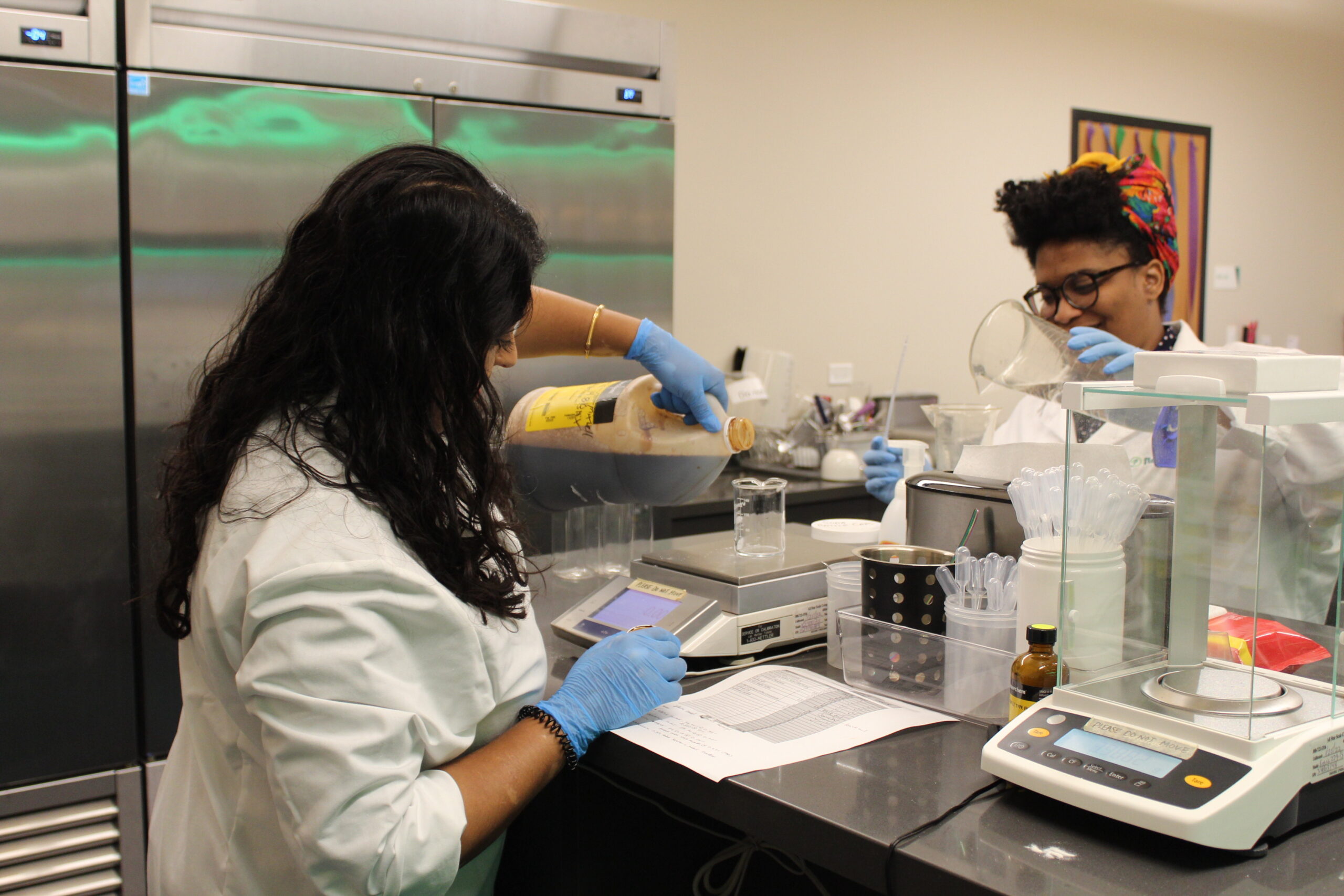

Pilot Processing

Dedicated to customer collaboration and support, our state-of-the-art pilot plant is a space for product development, testing, and filling. Within the space are separate sections for extractions and other experimental technologies, pilot thermal processing, aseptic bag-in-box (BIB) filling capabilities, and canning.

LEARN MORE

Quality & Regulatory Support

Our commitment to quality and safety is integrated into all aspects of Flavorchem’s operations. We monitor and analyze key performance indicators with a policy of continuous improvement, which is exemplified by our Safe Quality Foods (SQF) certification (USA) and BRC certification (Europe).

Sensory Capabilities

We know what it takes to make a product taste great. Our team of qualified panelists conduct sensory tests and flavor evaluations to ensure your product exceeds the highest taste standard.

Learn More

The Bench: Turnkey Beverage Development

Our comprehensive beverage development services include everything you need to get your food or beverage product launch ready including regulatory, branding, and packaging support. As an extension of your team, we will work with you from flavor to finish to achieve your project goals.

LEARN MORE